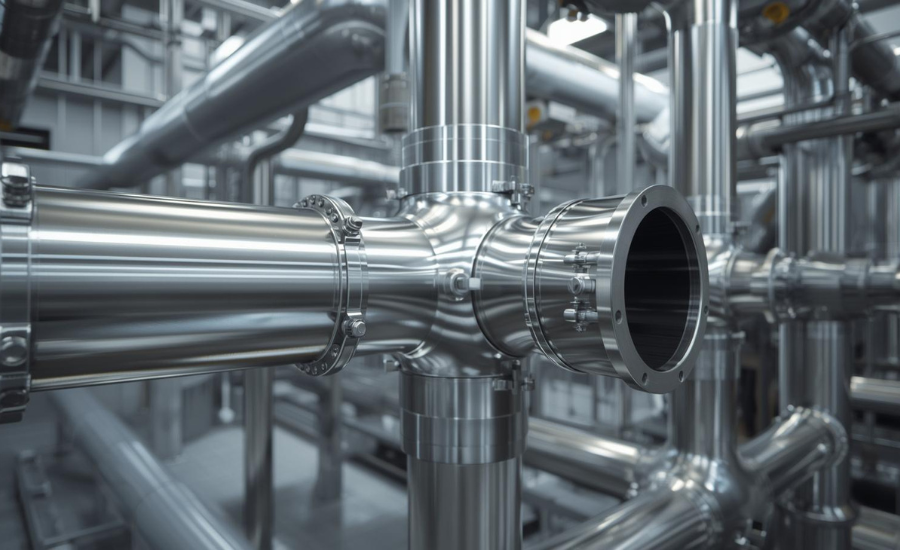

Efficient fluid flow is at the heart of any well-designed piping system—whether in chemical plants, food processing units, oil & gas facilities, or water treatment systems. When fluids move smoothly through pipes, equipment lasts longer, operating costs remain low, and the overall system performs at its best. One key component that plays a silent yet significant role in achieving this efficiency is the SS 304/304L Elbows.

These stainless steel bends, crafted from the workhorse grades 304 and 304L, are engineered to deliver superior performance with minimal flow resistance. Let’s explore how they enhance the hydraulic efficiency of piping systems across industries.

Smooth Curvature Ensures Minimal Turbulence

One of the biggest reasons SS 304/304L bends reduce flow resistance is their smooth, uniform curvature. Unlike sharp, angular turns, these bends guide fluid along a natural flow path.

This results in:

- Less turbulence

- Lower friction loss

- Reduced energy consumption

- Better pressure maintenance

In high-speed or high-volume pipelines, minimizing turbulence is essential for maintaining system stability and extending equipment life.

Long Radius Bends Improve Hydraulic Efficiency

SS 304/304L bends are often available in long radius (LR) designs, typically with a centerline radius 1.5 times the pipe diameter. These LR bends create a gentle directional change, allowing the fluid to maintain momentum without abrupt deceleration.

Benefits include:

- Lower head loss

- Smoother directional flow

- Fewer stress points in the pipe

- Enhanced pump performance

In contrast, short radius bends can create excessive pressure drops, especially in high-flow systems.

Seamless Construction Prevents Internal Obstructions

Many SS 304/304L Pipe Fittings are manufactured with seamless construction, which means no joints, weld lines, or irregularities inside the bend.

A seamless interior ensures:

- A continuous flow path

- Reduced chances of clogging

- Minimum erosion and wear

- Consistent pressure throughout the system

This makes seamless bends particularly valuable in sanitary industries like pharmaceuticals, dairy, and food processing, where hygiene and consistent flow are critical.

Corrosion Resistance Maintains Flow Efficiency over Time

Corrosion inside a pipe bend is a common reason for increased resistance. Pitting, scaling, and roughness on the inner surface disrupt fluid flow and increase pressure drops.

SS 304 and 304L are known for their:

- Excellent resistance to corrosion

- Smooth surface finish

- Low reactivity with chemicals

- Resistance to oxidation

This ensures that the internal surfaces remain smooth for years, maintaining optimal flow characteristics throughout the life of the system.

Lower Carbon Content in 304L Minimizes Sensitization

Grade 304L contains lower carbon than 304, which reduces the risk of carbide precipitation during welding. This enhances the structural integrity and prevents:

- Weak weld zones

- Corrosion at the heat-affected area

- Internal roughness that increases flow resistance

These benefits make 304L bends ideal for welded systems that must maintain long-term smooth flow.

Uniform Wall Thickness Ensures Balanced Flow Dynamics

High-quality SS 304/304L bends are manufactured with strict quality control to ensure uniform wall thickness throughout the curve. Inconsistent thickness can cause pressure variations within the bend, leading to undesirable flow behavior.

Uniform thickness provides:

- Consistent velocity distribution

- Smooth fluid transition

- Reduced vibration and noise

- Lower risk of erosion

Balanced flow dynamics ultimately enhance the reliability and efficiency of the entire pipeline.

Compatibility With Hygienic and High-Flow Applications

SS 304/304L bends are widely used in:

- Beverage and dairy lines

- Pharmaceutical plants

- HVAC systems

- Compressed air lines

- Water and wastewater treatment

In all these applications, stable, continuous flow is essential. Because of their hygienic surface finish and flow-friendly geometry, these bends deliver unmatched performance with minimal pressure loss.

Conclusion

In a piping system, every component matters—but bends play a particularly important role in determining how efficiently fluid travels from point A to point B. SS 304/304L bends are engineered to reduce flow resistance through smooth curvature, corrosion resistance, seamless interiors, and long-radius design.

Their ability to maintain consistent, low-turbulence flow not only enhances system performance but also reduces operational costs, protects equipment, and improves overall reliability.